WR FEEDER 400_case04

Wide Range for food: 30 kg of chocolate snack

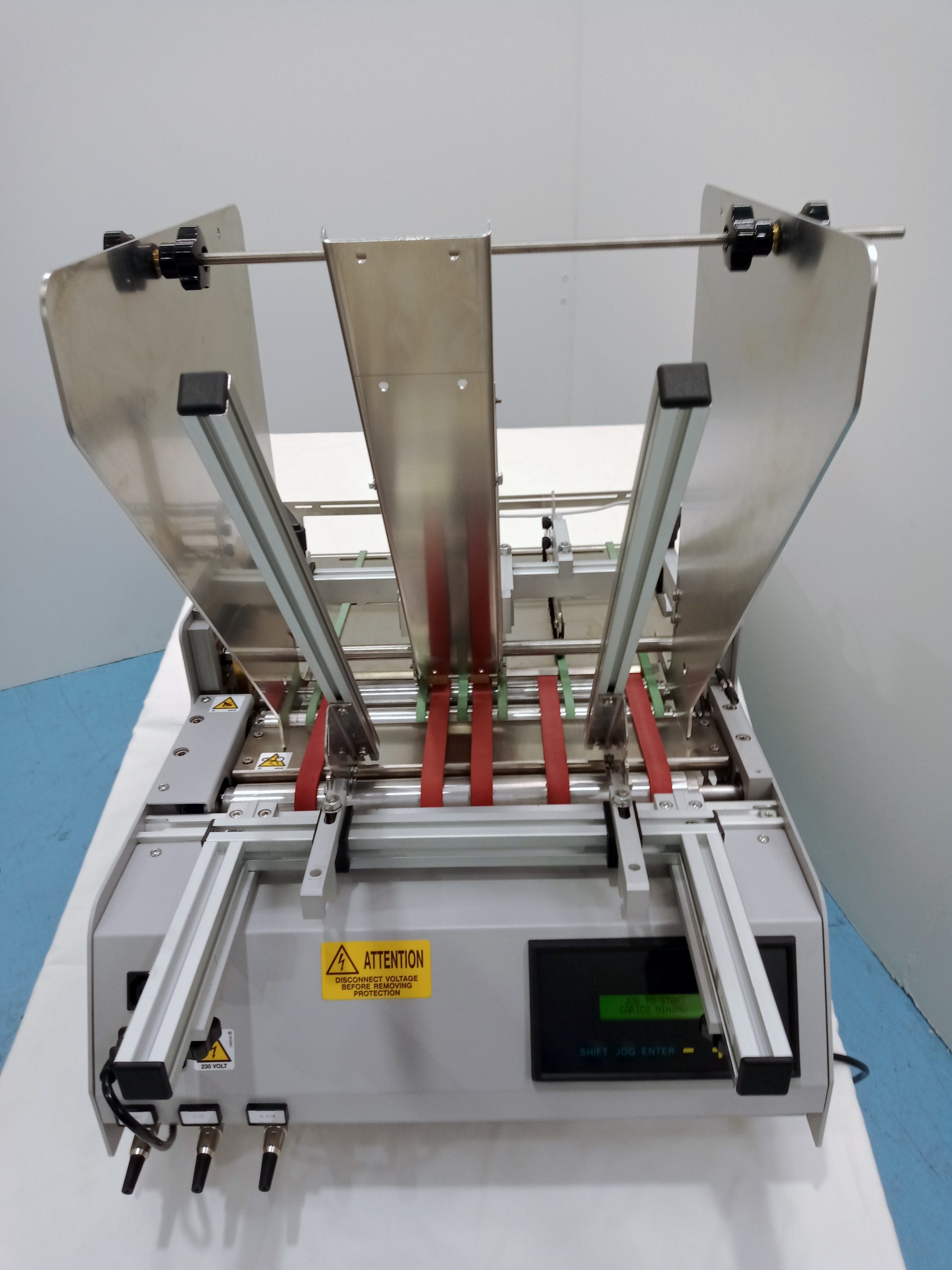

Type: WR FEEDER LABEL 400

Sector: food

This time the customer has really committed the Wide Range team severely to find a solution to his difficult request: to load as many cards in the feeder warehouse, as many as to allow a working autonomy of about 30 minutes on the production line. Once peeled, the products enter the folding, forming and gluing line.

Countless internal tests have been carried out and finally, once again, Wide Range has found the right solution.

If increasing the loading warehouse of the cardboard from 300 to 600 mm was practically taken for granted, the success in being able to feed a total product weight of about 30 kg was not at all guaranteed. This was possible thanks to the construction of some mechanical parts in stainless steel and aluminum: a guide positioned vertically and inclined by about 30 degrees to allow the cards to position themselves in an perfect manner before being peeled, two aluminum profiles, on the right and on the left, to support the weight of the cardboards and finally two stainless steel shoulders specially designed to hold the cards in the loading station.

This project represented a difficult challenge, which after a few days seemed impossible. Now we know that you can “peel” 30 kg of chocolate snacks at very high speeds and in continuous or by “on demand” mode.

Once again, a project bordering on the impossible!